The innovative technology behind CoPulsation™ is the use of two co-dependent solenoids that work in a coordinated manner to control the admission of vacuum and air to the pulsation chamber in the shell. This design eliminates all inefficiencies and permits the use of a very large diameter fresh air inlet effectively turbo-charging the pulsation.

The product consists of pulsators, controlling electronics to power the pulsators, shells, liners and splitter Tees.

|

|

|

CoPulsation™ pulsator in an exploded partial assembly configuration with the common output chamber exposed. This is a simultaneous pulsator. |

CoPulsation™ pulsator cut apart to show the large diameter fresh air inlet opening with not restriction. |

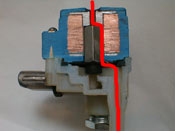

Conventional pulsator sectioned to show that a single solenoid controls both air and vacuum with a small fresh air inlet that requires the fresh air to be forced between the solenoid plunger and the solenoid windings. |

|

|

Compare the difference in fresh air paths through the two different pulsator designs. CoPulsation™ is a highly efficient design whereas the conventional is extremely restrictive |

|

|

|

CoPulsation™ |

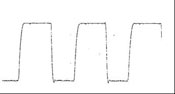

Conventional |

The above pulsation graphs show the difference in pulsation performance, both are measured at the shell |

|